With things rapidly moving ahead, the next item on the menu is the head. Singer was a leader in the introduction of the overhead cam shaft. This arrangement provides a more direct link between the cam and the valves they control. Great for simplicity! Well you would think so, more on that later.

With things rapidly moving ahead, the next item on the menu is the head. Singer was a leader in the introduction of the overhead cam shaft. This arrangement provides a more direct link between the cam and the valves they control. Great for simplicity! Well you would think so, more on that later. Now that the head and ports cleaned I proceeded to install the valves. A borrowed valve spring compressor came in handy (thanks Phil). One by one the valves were inserted and the collets put in place to secure them. Now I was ready to install the cam. Again, notes and/or photos of this area before dismantling will come in handy as the camshaft bearings are sided. The rear one is the tough one as each side is almost the same. The middle bearing has a port on the left side for the oil feed pipe and the forward bearing

Now that the head and ports cleaned I proceeded to install the valves. A borrowed valve spring compressor came in handy (thanks Phil). One by one the valves were inserted and the collets put in place to secure them. Now I was ready to install the cam. Again, notes and/or photos of this area before dismantling will come in handy as the camshaft bearings are sided. The rear one is the tough one as each side is almost the same. The middle bearing has a port on the left side for the oil feed pipe and the forward bearing  has an extension that points towards the front of the head. Once again, our slippery friend oil is used liberally in the bearings prior to installation. Tighten down the three pair of nuts that secure the cam bearings. I leave off the oil feed pipe for now. It interferes when tightening the head nuts. Speaking of these, this is a good time to install the two short studs on the bottom of the head, they are the tricky ones to deal with when torquing everything down.

has an extension that points towards the front of the head. Once again, our slippery friend oil is used liberally in the bearings prior to installation. Tighten down the three pair of nuts that secure the cam bearings. I leave off the oil feed pipe for now. It interferes when tightening the head nuts. Speaking of these, this is a good time to install the two short studs on the bottom of the head, they are the tricky ones to deal with when torquing everything down.Install the head gasket. Before putting it in place, I wipe it down with a lightly oiled rag.

Now we can "drop" the head in place. Drop gently I mean. Care again is taken to ensure that the head gasket is not pinched and that the head settles evenly. Now we can put on the washers on the studs and screw on the head nuts finger tight for now. Remember again the two studs hiding under the manifold.

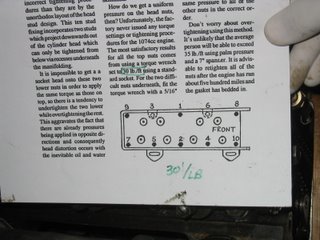

Now we tighten. I followed the torque settings that I used from the Bill Haverly article. Also important is the sequence for tightening the nuts. The head must settle down evenly so as not to introduce any twisting which will lead to gaps between the head and block, which leads to water mixing with oil, or in the cylinder, or worse (is there anything worse?)

I used a crowfoot on a short extension for the hidden nuts. There are difficult to access AND since I am tightening them from above, I had to remember to switch the torque wrench to loosen.

I used a crowfoot on a short extension for the hidden nuts. There are difficult to access AND since I am tightening them from above, I had to remember to switch the torque wrench to loosen.I tightened down the head in two stages. 20 foot pounds for the first pass, 30 for the final one. Each time following the tightening pattern as outlined in the article.

There is still the oil feed pipe from the block and its continuation to the center cam bearing. I would leave them for now, at least until the cam timing procedure has been completed... timing

There is still the oil feed pipe from the block and its continuation to the center cam bearing. I would leave them for now, at least until the cam timing procedure has been completed... timing... timing ...

... timing ...

Timing is everything... and that is for the next chapter.

No comments:

Post a Comment